|

|

|

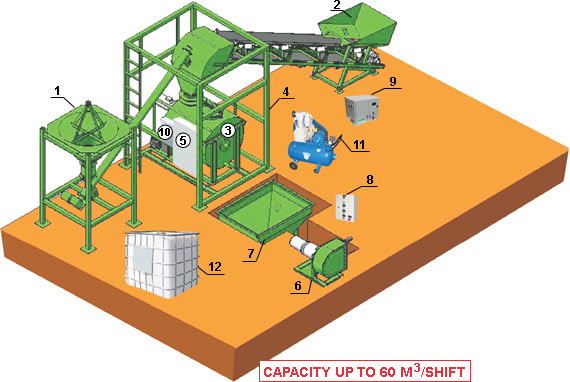

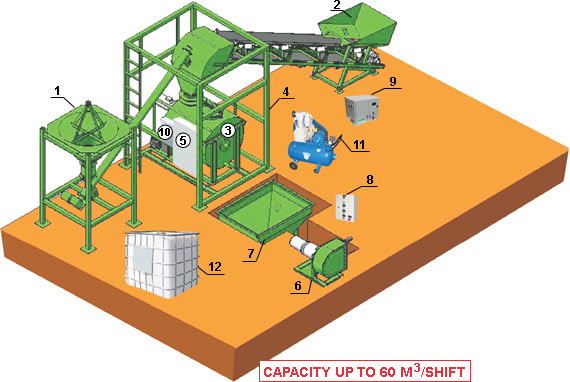

АМК "StroyFoamBeton 60 COMPACT"

1 - Bulk bags unloader SR 500 (1000) with screw conveyor VK (3,5 m by length) (cement conveying); 2 - Belt conveyor LK500 (5m long) with feed bin (sand conveying); 3 - Mixing complex RBS 1000 HYACINTH; 4 - Foundation frame with weighting system for mixing plant RBS HYACINTH 1000; 5 - Automated control system of the line SAU 600 LOGIC; 6 - Hose pump KORNET 7; 7 - Receiving bin of hose pump KORNET 7; 8 - Hose pump KORNET 7 control board; 9 - Automatic water pump batcher POTOK 8.150; 10 - Control box of pneumatic system; 11 - Air compressor; 12 - Water tank of 1 m³.

Nowadays foam concrete and foam concrete products are in great demand in the Russian construction market. Last time the demand for automated production lines capacity from 40 to 100 m³ and more for foam concrete production lines increased. The cause is the minimal use of manual labor. The engineering enterprise "Stroymechanika" being a leading manufacturer and designer of equipment for foam concrete production, offers the unique automated compact lines "StroyFoamBeton COMPACT" (hereinafter in the text AMK "StroyFaomBeton COMPACT").

The lines AMK "StroyFaomBeton COMPACT" are the unique serial automated lines in Russia, intended directly for foam concrete production.

The lines AMK "StroyFoamBeton COMPACT" have high output at compact dimensions. The production of foam concrete of low densities (from 300 kg/m³) became possible using АМК "StroyFoamBeton COMPACT" line.

The competitive advantages of АМК "StroyFoamBeton COMPACT" line are:

- Operation in manual and automatic mode due to high automation level;

- Application of parts of well-known world manufacturers: parts for pneumatic system of

company (FESTO, Germany), gear motors of company (FESTO, Germany), gear motors of  company (Motowario, Italy), components for control box of company (Motowario, Italy), components for control box of  company (LG, South Korea), company (LG, South Korea),  company (ABB, Germany), logic controllers of company (ABB, Germany), logic controllers of  company (ABC-MK, Russia) – provide the reliability of the complex; company (ABC-MK, Russia) – provide the reliability of the complex;

- Quick payback of the complex due to low price;

- The universality of applied raw materials helps to operate with different materials;

- High batching accuracy of used materials (0,1% - 0,2%) helps to low prime cost;

- The considerable power saving due to low power consumption;

- The geometrical accuracy and well-designed general view of ready products will satisfy the most exacting customer;

- High capacity ensures the productive efficiency;

- The autonomy of the line gives possibility to exploit line directly on the building site;

- Short putting into operation period makes possible to start manufacturing and selling of products as quick as possible.

The intelligent automatic control system SAU 600 LOGIC, controls the complex АМК "StroyFoamBeton 60 COMPACT". It is developed by well-known Russian company "AVS-MK" – partner of the engineering company "Stroymechanika" especially for this line. The system operates both automatically and manually.

The application of system SAU 600 LOGIC permits to reduce personnel, working on the construction site, that have a positive influence on payback period and quality of ready products.

The distinctive features of AMK "StroyFomBton 60 COMPACT":

- The unit design of "COMPACT" series is made without application of the batcher of inert and binding materials. The sand and cement are batched just in the mixer’s tank that is equipped with reliable and high-precision weighing system. It helped to reduce the size of the line and made easier the search of appropriate production premises to install the production line.

- A new development of engineering enterprise "Stroymechanika" – peristaltic (hose) mortar pump KORNET 7 is applied in the AMK "StroyFoamBeton 60 COMPACT" instead of screw pump of "SOSNA" series. The mortar pump is equipped with a bin to receive material from mixing plant, that helps to convey material continuously at application of ) batch-type mixing equipment. The main advantages of mortar pump is: saving of structure of pumping medium, total tightness, lack of sealing, batched mortar conveyance, reverse operation, self-cleaning of the pump by changing the rotation direction.

Content of the complex AMK "StroyFoamBeton 60 COMPACT" capacity of 60 m³/shift:

| № п/п |

Nomination |

Technical characteristics |

Quantity, ps. |

| 1 |

Bulk bags unloader SR 500 (1000) with screw conveyor (3,5 m long) (cement conveying) |

Overall dimensions 1560×1560×2200 mm

Weight 350 kg |

1 set |

| 2 |

Belt conveyor LK 500 (5 m long) with feed bin (sand conveyance) |

Overall dimensions 8000×1020×595 mm

Weight 350 kg |

1 set |

| 3 |

Mixing plant RBS 1000 HYACINTH |

Overall dimensions 1750×1200×1850 mm

Power consumption 11 kW

Capacity up to 10 m³/h |

1 set |

| 4 |

Foundation frame with weighting system for mixing plant RBS HYACINTH 1000 |

Overall dimensions 2060×2060×3117 mm |

1 set |

| 5 |

Automated control system SAU 600 LOGIC |

LG element base

Overall dimensions 600×360×600 mm

Weight 50 kg |

1 set |

| 6 |

Peristaltic (hose) pump KORNET 7 |

Overall dimensions 1190×850×641 mm

Weight 170 kg |

1 set |

| 7 |

Receiving bin of peristaltic pump KORNET 7 |

Overall dimensions 1300×1100×1100 mm

Weight 250 kg |

1 set |

| 8 |

Control board of peristaltic pump KORNET 7 |

|

1 set |

| 9 |

Automatic water pump batcher POTOK 8.150 |

Overall dimensions 600×430×350 mm

Power consumption 1,2 kW

Weight 30 kg |

1 set |

| 10 |

Control board of pneumatic air-operated system |

Overall dimensions 600×500×200 mm

Weight 30 kg |

1 set |

| 11 |

Air compressor К 2 |

Overall dimensions 130×62×125 mm

Power consumption 5,5 kW |

1 set |

| 12 |

Water tank 1 m³ |

Overall dimensions 1000×1000×1000 mm

Weight 10 kg |

1 set |

Technical characteristics

| Capacity, m³/shift |

up to 60 |

| Installed capacity, kW |

50,8 |

| Weight, kg |

˜ 3000 |

| Total production area, m² |

от 400 |

| Ceiling height, mm |

from 3500 |

|

|

| Water pump batcher POTOK 8.150 |

Mixing complex RBS of "HYACINTH" series |

|

|

| Belt conveyor LK 500 |

Peristaltic (hose) pump KORTNET 7 |

|

|

| Bulk bags unloader SR 500 with screw conveyor of "VK" series |

Water tank of 1 m³ |

The delivery set includes:

- Operating manual.

- Technical schedule for production of articles of AMK "StroyFoamBeton".

- Staff training to work with equipment.

Optional services:

|

|

company (FESTO, Germany), gear motors of

company (FESTO, Germany), gear motors of  company (Motowario, Italy), components for control box of

company (Motowario, Italy), components for control box of  company (LG, South Korea),

company (LG, South Korea),  company (ABB, Germany), logic controllers of

company (ABB, Germany), logic controllers of  company (ABC-MK, Russia) – provide the reliability of the complex;

company (ABC-MK, Russia) – provide the reliability of the complex;