|

|

StroyMechanika LTD |

||||||||||||

|

|

|||||||||||||

| CORNET 7000 | Links | |||||||||||||

|

Peristaltic pump (hose-type) grouting pump CORNET 7000

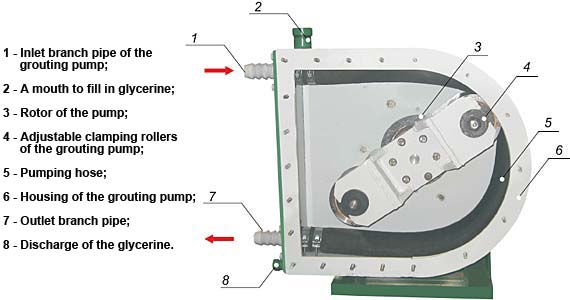

The peristaltic pump (hose-type) mortar pump CORNET 7000 by the engineering enterprise "Stroymechanika" is intended to pump and batching conveying of chemical active and neutral liquids, high-abrasive, high-viscous mediums of the density up to 3000 kg/m³ at temperature from -20 °С to +70 °С. The pumping of the materials inclined to lamination which components differs considerably by density, viscous and abrasive masses, such as building mortars, foam concrete and polystyrene concrete mixes are not the full range of the problems successfully solved with use of peristaltic (hose-type) pumps of series "CORNET". The peristaltic (hose-type) grouting pump of series "CORNET" is a volume self-priming pump those working part is the special rubber hose. The pump CORNET 7000 includes a case, a gear motor mounted on the case and being a grouting pump actuator, a rotor with two adjustable clamping rollers, a hose and branch pipes (inlet and outlet). At gear motor operation the torque moment enteres a rotor working in the glycerin of which clamping rollers press completely and are rolled on the hose installed around internal perimeter of the pump case, thus the medium which is before the roller, is completely pressed out in the outlet pipeline. Behind clamping rollers the hose restores fully its form and sucks the portion of the pumping medium. The abrasive particles are pressed into the elastic inner layer of the hose, then, pushed out in the flow, not damaging the hose. It is admitted the presence of solids in the pumping mortar. Their size is no more than 10% in total weight and no more than 15% from the internal diameter of the hose for single particles. Replacement of working hose:

The application with construction mixes operation:

The grouting pumps of "CORNET" series are applied on the construction sites together with mixers BSL 500 DELTA, COMPASS 300 SUPERMIX and with turbulent mixers NAVIGATOR V3 at flooring and floor heat insulation, as well as at pouring of fresh mix into a mould.

Peristaltic (hose-type) grouting pump "CORNET" can be equipped with a hopper to receive material from a mixer. The service bin of the pump allows to convey material continuously using the batch-type mixers that is especially important at works, where the break is not permitted or absolutely denied (mechanical plastering, pouring of forms etc.). The pumping units are also equipped with wheel chassis to make easier the transportation through building sites.

Optional packaging arrangement:

Composition of the pump

Overall dimensions

Technical characteristics

Peristaltic pump "CORNET" is a combination of simplicity of design, reliability and high pump capacity at compact dimensions.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| © 2004-2009 "Stroymachanika" LTD | Catalogue Dealers About us News Contacts Site map |

Application of peristaltic pump as a batcher:

Application of peristaltic pump as a batcher:

Competitive advantages of peristaltic (hose-type) pump:

Competitive advantages of peristaltic (hose-type) pump:

(MOTOVARIO, Italy) production as pump actuator.

(MOTOVARIO, Italy) production as pump actuator.