|

|

StroyMechanika LTD |

||||||||||||

|

|

|||||||||||||

| AMK "StroyFoamConcrete 40", AMK "StroyFoamConcrete 80" | Links | |||||||||||||

|

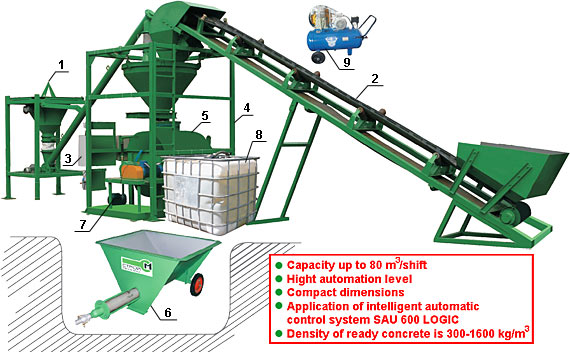

Automated modular complexes (АМK) "StroyFoamConcrete"

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| № | Designation | Technical characteristics | Quantity, ps. |

|---|---|---|---|

| 1 | Bag unloader SR-500 with screw conveyor (6 meters long) (cement conveyor) | Overall dimensions 1560×1560×2200 mm power consumption 5,5 kW |

1 set |

| 2 | Belt conveyor LK 500 (7,4 m long) with feed hopper | Overall dimensions 8000×1020×595 mm power consumption 5 kW capacity 10 t/hour |

1 set |

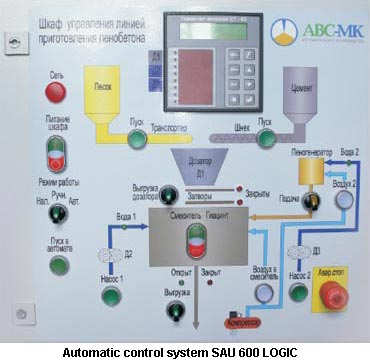

| 3 | Automatic control system SAU 600 LOGIC | LG-based Overall dimensions 600×360×600 mm |

1 set |

| 4 | Batching hopper of inert and binding materials with knife shutter | Overall dimensions 2060×2060×3117 mm knife shutter pneumatic drive of "FESTO" production |

1 set |

| 5 | Mixing complex RBS 500 HYACINTH | Overall dimensions 1400×1650×1200 mm power consumption 7,5 kW capacity up to 5 m³/hour |

1 set |

| 6 | Automatic pump water batcher POTOK 8.150 | Overall dimensions 600×430×350 mm power consumption 1,2 kW |

1 set |

| 7 | Compressor K-11 | Overall dimensions 100×47×80 mm power consumption 2,2 kW |

1 set |

Content of the complex AMK "StroyFoamConcrete 80" capacity 80 m³/shift

| № | Designation | Technical characteristics | Quantity, ps. |

|---|---|---|---|

| 1 | Bag unloader SR-500 with screw conveyor (6 meters long) (cement conveyor) | Overall dimensions 1560×1560×2200 mm power consumption 5,5 kW |

1 set |

| 2 | Belt conveyor LK 500 (7,4 m long) with feed hopper | Overall dimensions 8000×1020×595 mm power consumption 5 kW capacity 10 t/hour |

1 set |

| 3 | Automatic control system SAU 600 LOGIC | Элементная база LG Overall dimensions 600×360×600 mm |

1 set |

| 4 | Batching hopper of inert and binding materials with knife shutter | Overall dimensions 2060×2060×3117 mm knife shutter pneumatic drive of "FESTO" production |

1 set |

| 5 | Mixing complex RBS 1000 HYACINTH | Overall dimensions 1750×1200×1850 mm power consumption 11 kW capacity up to 10 m³/hour |

1 set |

| 6 | Automatic water pump batcher POTOK 8.150 | Overall dimensions 600×430×350 mm power consumption 1,2 kW |

1 set |

| 7 | Compressor K-2 | Overall dimensions 130×62×125 mm power consumption 5,5 kW |

1 set |

|

|

| Water pump batcher POTOK 8.150 | Mixing complex RBS of series "HYACINTH" |

|

|

| Belt conveyor LK 500 | Screw pump of series "SOSNA" |

|

|

| Bag unloader SR 500 with a screw conveyor | Water tank |

Every construction unit of the complex "StroyFoamConcrete" is tested before to be supplied to customer.

Optional technological equipment:

- metal moulds of series "LAZERFORM",

- metal plastic moulds of series "VERGELOCK",

- metal moulds of series "PROFI",

- silos of 20 m³ and 40 m³ by volume,

- crushing complex MOLOT 4500,

- lifting device PU 03.

The complex is supplied with:

- operating manual;

- operating manual on SAU 600 LOGIC;

- technical schedule on product production on the complex АМК "StroyFoamConcrete";

- personnel training.

| Optional equipment |

| Chemical agents |

| About us | ||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

| Services | ||||||||||||||||||||||||

|

Consultations and services in the building materials production Development of technical specifications and technological schedules Contract supervision of the equipment |

||||||||||||||||||||||||

| Our dealers | ||||||||||||||||||||||||

|

||||||||||||||||||||||||

| © 2004-2009 "Stroymachanika" LTD | Catalogue Dealers About us News Contacts Site map |

company (Germany), gear motor of CHIARAVALLI TRANSMISSIONI company (Italy), components for control box of

company (Germany), gear motor of CHIARAVALLI TRANSMISSIONI company (Italy), components for control box of  company (South Korea),

company (South Korea),  company (Germany), logic controllers SAU 600 LOGIC of

company (Germany), logic controllers SAU 600 LOGIC of  company - provide the reliability of the complex;

company - provide the reliability of the complex; System SAU 600 LOGIC adjusts the operation of:

System SAU 600 LOGIC adjusts the operation of: