Turbulent mixer NAVIGATOR V3

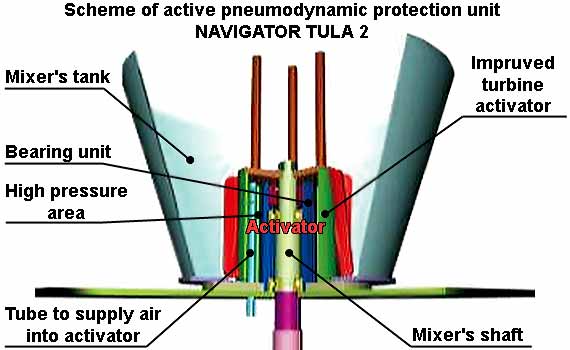

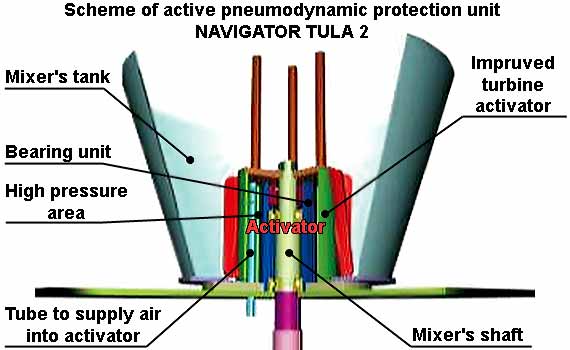

(application of active pneumatic protection unit NAVIGATOR TULA II)

The turbulent mixer NAVIGATOR V3 by production of machine building company "Stroymechanika" is intended for foam concrete production of density from 300 to 1600 kg/m³ and its conveying to the laying place through concrete pipeline. It allows to underpour floors and roofs, fill hollows, produce blocks of different dimensions and density. The turbulent mixer NAVIGATOR V3 by production of machine building company "Stroymechanika" is intended for foam concrete production of density from 300 to 1600 kg/m³ and its conveying to the laying place through concrete pipeline. It allows to underpour floors and roofs, fill hollows, produce blocks of different dimensions and density.

Turbulent mixer NAVIGATOR V3 includes an immobile barrel-shaped tank with the cone bottom fixed on the frame, a blade rotor – activator, located on the bottom of the tank, electric motor and drive pulleys. Control elements of the mixer together with the device of air adjustment are concentrated on control rack that is fixed on the mixer’s frame.

The improved activator relating to NAVIGATOR TULA is installed in the turbulent mixer NAVIGATOR V3. A new system of active pneumodynamic protection NAVUIGATOR TULA 2 is applied. The enlarged turbulent activator, improved blades location on the activator, interacted hydraulically and dynamically with immobile blades located on mixer’s walls. This allowed to reach more homogeneous aeration of mix and, accordingly, more stable characteristics of ready mix as well as to enlarge density range of ready foam concrete . The enlarged manhole helps to load mix components in plant’s working tank quickly and easily.

Activation of foaming agents in mixer NAVIGATOR V3 takes place due to high rotation speed of activator located in the bottom of mixer’s tank. This allows eliminate foam generator at foam concrete production.

The turbulent method based on creation of high velocity gradient, favours the uniform distribution of agents and impurities (fibre, pigments, plasticizing agents) in preparing mix.

Due to simple design and good operating characteristics the turbulent mixers of series "NAVIGATOR" are widely used by manufacturers of building materials. Some restrictions of use are greatly compensated by high mixing speed, easiness in maintenance of the plant.

Turbulent mixers of series "NAVIGATOR" allows to produce qualitative material and receive constant results from batch to batch. The ready material corresponds to GOST 25485-89 and has density from 300 to 1600 kg/m³.

Competitive advantages of the turbulent mixer NAVIGATOR V3:

- unit of active pneumodynamic protection NAVIGATOR TULA 2;

- compact overall dimensions;

- quick pay back;

- easy in maintenance;

- application of qualitative components of well-known world manufacturers:

components for pneumatic system; components for pneumatic system;  electric components. electric components.

Technical characteristics

| Overall dimensions (L×W×H), mm |

1520×1020×1660* |

| Weight, kg |

325 |

| Power consumption, kW |

7,5 |

| Working air pressure, atm |

0,65 |

| Air consumption, l/min |

160 |

| Power, V |

380 |

| Working volume of a tank, l |

500 |

Capacity at the non-autoclave foam concrete production:

- at manual loading, m³/h

- at automatic loading, m³/h |

3

6 |

| Foam concrete production cycle, min |

3-6 |

Distance of mix supply:

- horizontally, m

- vertically, m |

20

5 |

* possible to deliver in three tones container

The delivery set of turbulent mixer NAVIGATOR V3 includes:

- technology of foam concrete production;

- personnel training;

- mortar compositions;

- complementary documentation;

- 5 meters of rubber hose for distance discharge of mortar.

Each client receives the technical and technological consultation upon questions of foam concrete production regardless of order volume. Buying a mixer for foam concrete mixing each client is provided with technological schedule on porous concrete (foam concrete) masses, with practical recommendations, basic requirements to used components, and test methods of received material.

| Optional equipment |

|

| Chemical agents |

|

|

The turbulent mixer NAVIGATOR V3 by production of machine building company "Stroymechanika" is intended for foam concrete production of density from 300 to 1600 kg/m³ and its conveying to the laying place through concrete pipeline. It allows to underpour floors and roofs, fill hollows, produce blocks of different dimensions and density.

The turbulent mixer NAVIGATOR V3 by production of machine building company "Stroymechanika" is intended for foam concrete production of density from 300 to 1600 kg/m³ and its conveying to the laying place through concrete pipeline. It allows to underpour floors and roofs, fill hollows, produce blocks of different dimensions and density.

components for pneumatic system;

components for pneumatic system;  electric components.

electric components.