|

|

StroyMechanika LTD |

||||||||||||

|

|

|||||||||||||

| KORVET 300 OPTIMIX | Links | |||||||||||||

|

Mortar mixing machine KORVET 300 OPTIMIX

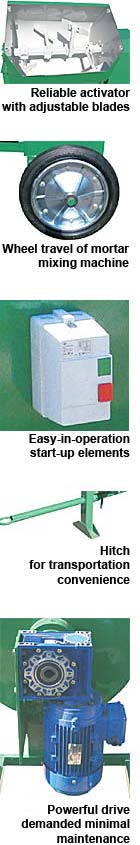

Mortar mixing machine KORVET 300 OPTIMIX by the production of machine building plant "Stroymechanika" is intended to make plasters and masonry mortars applied on the building site, as well as to make high-quality mixes to be used in the production of paving tile, and ornamental concrete elements. Applying mortar mixing machine the preparation of mix with aggregate size of 5 mm is possible. The compact overall dimensions and small weight of the mortar mixing plant allow to work with it just too close from the application place of ready mortar. The mortar mixing machines "KORVET" operate on production areas, construction sites, and inside the working shops too. Mortar mixing machines are supplied ready for operation, oiled, and with adjusted clearances of operating blades. The mixing of components is made by mixing device which represents a shaft with blades installed on it. The design of mixing blades of mortar mixing machine helps to make multicomponent homogeneous mortars as quick as possible, and helps to reach the optimal discharge speed of ready mortar. The configuration of mixer's blades allows to work as quick as possible with mixes of different density and mobility, as well as to prepare multicomponent building mortars. Mortar mixing machines of KORVET series are easy to move around construction site or other territory due to pneumatic wheels, they are equipped with supporting foots with adjustable working weight. The design of mixer's tank and quick-release activator's shaft of composite construction restricts the service and repair period of mortar mixing machine, the adjustment of blades offset helps to clean the mixer's walls as full as possible. The characteristics above mentioned certify about excellent operational features of mortar mixing machine KORVET 300 OPTIMIX, its high productivity and reliability. Competitive advantages of mortar mixing machine KORVET 300 OPTIMIX:

Overall dimensions

Technical characteristics

Mortar mixing machine KORVET are compact, reliable, simple units helping to make qualitative multicomponent mixes at minimal initial investments.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| © 2004-2009 "Stroymachanika" LTD | Catalogue Dealers About us News Contacts Site map |