Universal cutting plant RIF-1

The universal cutting plant RIF-1 is intended to make wall and partition cellular concretes (foam concrete, gas concrete and polystyrene concrete) with geometrical deviations from given dimensions but no more than ±1mm from the block with overall dimensions up to 1200×1200×600 mm in shops. The reached cutting accuracy helps to lay blocks on glue or thin-layer mortars. The universal cutting plant RIF-1 is intended to make wall and partition cellular concretes (foam concrete, gas concrete and polystyrene concrete) with geometrical deviations from given dimensions but no more than ±1mm from the block with overall dimensions up to 1200×1200×600 mm in shops. The reached cutting accuracy helps to lay blocks on glue or thin-layer mortars.

The cellular concrete (foam concrete, gas concrete and polystyrene concrete) with flat porous design made in accordance with GOST 25485-89 is used for cutting. The material hardened up to state suitable for cutting (12 hours and more after underpouring into mould) is used for cutting on the plant RIF-1.

Operation on cutting plant.

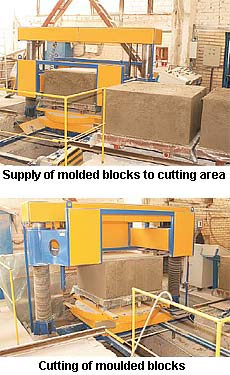

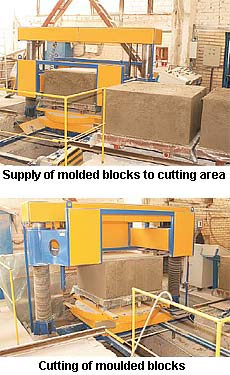

The cellular concrete mix is poured into portable metallic moulds FORMBLOCK-MASSIVE, specially designed to be used on eth cutting area. The portable mould FORMBLOCK-MASSIVE used as a part of cutting plant is easy in exploitation. It take 2-3 minutes to clean, grease and assemble one mould. The plant operates by following way. The trolley with pallets and installed massive hardened is gripped by special conveyor and enters the cutting plant RIF-1 to be cut. On the first stage the upper crust (30 mm) by screw cutter and the length of eth block is moulded (600 mm). The bottom side of the massive has strictly horizontal surface due to application of rigid sheet of thick phenol-base plywood. On the second stage the massive is cut horizontally and longitudinally by horizontal saw lifting and falling the cutting unit consecutively, the cutting step and the dimensions of width and height of the clock are determined by operation of coordinate table. After that the cut massive is supplied to tunnel chambers for thermal processing. The cutting plant RIF-1 set includes a unit for shaping of crust, one horizontal contour band unit, and coordinate conveying device. All mechanisms has electric drive adjustable ny frequency.

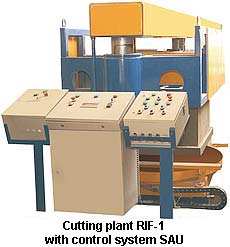

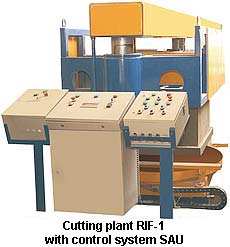

The cutting plant RIF-1 is equipped with handy and easy-to-use control system SAU. The required cut parameters (block dimensions) are set up from electronic operator's panel. The reconfiguration of the cutting plant for other parameters is not required. Besides that the display of operator's panel reflects the information to analyse the operation of the plant in real-time mode. The cutting plant RIF-1 is equipped with handy and easy-to-use control system SAU. The required cut parameters (block dimensions) are set up from electronic operator's panel. The reconfiguration of the cutting plant for other parameters is not required. Besides that the display of operator's panel reflects the information to analyse the operation of the plant in real-time mode.

The cutting plant can manually-controlled for adjustment of the cutting plant RIF-1 or operation in semi-automatic mode. The placement and transportation of the massive to be cut is made on the coordinate table of the cutting plant.

The automated control system (CAM) of the cutting plant.

The cutting plant can controlled in both manual and automatic modes due to application of the automated control system SAU. The CAM system SAU of the cutting plant includes control chamber with control board, cables, and set of probes required for operation of the plant in automatic mode. The control of the cutting plant in automation mode is made by pressing the button "START" on the front panel of the control chamber and the massive is cut into blocks in automatic mode.

The competitive advantages of the cutting plant RIF-1: The competitive advantages of the cutting plant RIF-1:

- The high automation degree of the cutting complex, the operation in both automatic as manual modes are possible due to application of the automated system SAU.

- Low power consumption became possible with the application of power-intensive high-torque drives.

- High capacity of the complex will provide the productive efficiency.

- The quick payback is possible thanks to attractive price.

- The short period of putting into operation allows to start the production and selling of the products as quick as possible.

- The geometrical accuracy and good appearance of the made products will satisfy the hard-to-please client.

- The application of the carriages as a hydraulic drives helps to minimize the power inputs.

- The quick reconfiguration of the plant to produce blocks of any dimensions.

- The operation as in automatic as in manual mode due to high automation level.

- Application of the qualitative and reliable components.

Applying the cutting plant RIF-1 on the production site helped to enlarge the range of launched products, as the application of one mould FOMRBLOCK MASSIVE allows to make blocks of 5 standard dimension types. Besides that, the moulds FORMBLOCK MASSIEV are cheaper in some times than the cassette moulds, and the production of such moulds does not require complex equipment, that's why the customer can make them by himself.

Technical characteristics

| Ready block capacity, m³/h |

5 |

| Rated power, kW |

4,5 |

| Floor surface of the tool with coordinate handling device, mm |

4,6×4,5 |

| Weight, kg |

3500 |

| Accuracy of cutting, mm |

±1 |

| Cutting elements |

Screw cutter and saw band |

| Blades quantity |

1 |

| Saw cut width, mm |

from 1,1 up to 1,5 |

| Maximal height of the cutter, mm |

600 |

| Dimensions of moulds to get foam concrete massive, mm |

1240×1240×600 |

| Dimensions of block, basic standard size, mm |

200×300×600 |

| Output of ready product from one massive, m³ |

0,86 |

| Cutting speed of one massive in automatic mode |

9,5 |

| Reconfiguration period for new dimension, min |

1 |

| Replacement period of saw blade, min |

5 |

| Lifting device actuator |

Electro-mechanical |

| Operation modes |

Automatic, semi-automatic, manual |

| Admissible density, kg/cm³ |

from 2 up to 15 |

|

The universal cutting plant RIF-1 is intended to make wall and partition cellular concretes (foam concrete, gas concrete and polystyrene concrete) with geometrical deviations from given dimensions but no more than ±1mm from the block with overall dimensions up to 1200×1200×600 mm in shops. The reached cutting accuracy helps to lay blocks on glue or thin-layer mortars.

The universal cutting plant RIF-1 is intended to make wall and partition cellular concretes (foam concrete, gas concrete and polystyrene concrete) with geometrical deviations from given dimensions but no more than ±1mm from the block with overall dimensions up to 1200×1200×600 mm in shops. The reached cutting accuracy helps to lay blocks on glue or thin-layer mortars. The cutting plant RIF-1 is equipped with handy and easy-to-use control system SAU. The required cut parameters (block dimensions) are set up from electronic operator's panel. The reconfiguration of the cutting plant for other parameters is not required. Besides that the display of operator's panel reflects the information to analyse the operation of the plant in real-time mode.

The cutting plant RIF-1 is equipped with handy and easy-to-use control system SAU. The required cut parameters (block dimensions) are set up from electronic operator's panel. The reconfiguration of the cutting plant for other parameters is not required. Besides that the display of operator's panel reflects the information to analyse the operation of the plant in real-time mode. The competitive advantages of the cutting plant RIF-1:

The competitive advantages of the cutting plant RIF-1: