|

|

StroyMechanika LTD |

||||||||||||

|

|

|||||||||||||

| STRING 500 | Links | |||||||||||||

|

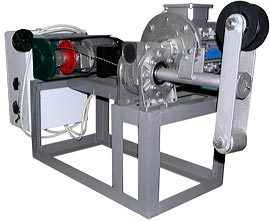

The installation to wind strings STRING 500

The special characteristic of widespread models of cutting complexes (the universal cutting complex (URK) MASTER PLUS) is that the cutting process of the cellular concrete mass (foam concrete, gas concrete) into small-piece articles, such as blocks and slabs is carried out with the application of metal strings. The cutting process is carried out with dry mass of foam concrete. The application of poor-manufactured strings will be characterized that the foam concrete mass will be cut not fully at the centre of foam concrete mass caused by the string bending at the resistance of the air brick to be cut, as well as by deviation from cut surface. Thus, the manufacturing of the strings used to cut cellular concrete mass, the application of the special equipment is required. The engineering plant "Stroymechanika" offers the installation to wind strings STRING 500. The installation is intended to wind the wire strings. They helps to cut the cellular concrete mass (foam concrete, gas concrete) on articles of the specified overall dimensions. It is possible to make twisted single-lay circular section string with the application of the installation STRING 500. The advantages of string application, made on the installation STRING 500:

Composition of the unit STRING 500:

Technical characteristics

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| © 2004-2009 "Stroymachanika" LTD | Catalogue Dealers About us News Contacts Site map |

To make cellular concrete blocks (foam concrete, gas concrete) upon cutting technology, the cutting equipment from the elementary machines to hi-tech automated cutting complexes are used.

To make cellular concrete blocks (foam concrete, gas concrete) upon cutting technology, the cutting equipment from the elementary machines to hi-tech automated cutting complexes are used. company (CHIARAVALLI TRASMISSIONI, Italy), is used to wind fine wire around central wire;

company (CHIARAVALLI TRASMISSIONI, Italy), is used to wind fine wire around central wire;