|

|

StroyMechanika LTD |

||||||||||||

|

|

|||||||||||||

| AMK "StroyFoamBeton 80 SK" | Links | |||||||||||||

|

Automated foam concrete production line

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

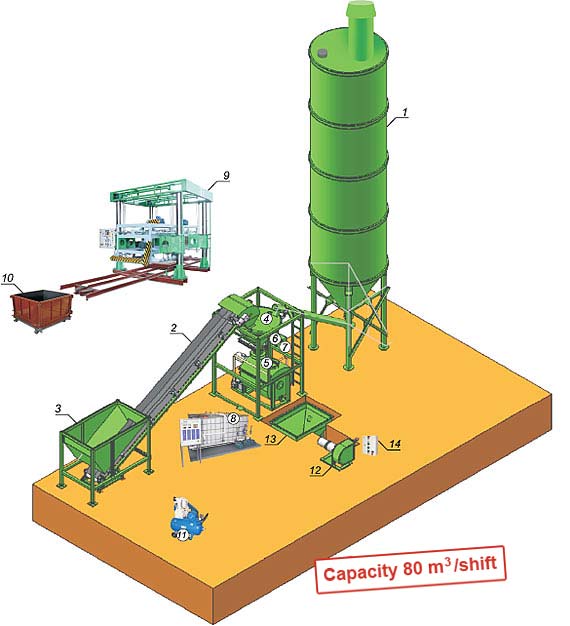

1 - Cement silo 50 m³ with screw conveyor of VK 219 series; 2 - Belt conveyor LK 500; 3 - Feed bin for inert and binding materials RB 3000; 4 - Metering bin for inert and binding materials with knife gate; 5 - Mixing plant RBS 1000 HYACINTH with slide gate and air-operated drive; 6 - Automated control system of the line SAU 600 LOGIC; 7 - Control chamber of pneumatic system of the line; 8 - Preparation and batching plant for liquid components SJK 4000; 9 - Universal cutting plant URK MASTER LOGIC; 10 - Metal mould FORM-BLOCK MASSIVE; 11 - Air compressor К 2; 12 - Peristaltic (hose) pump KORNET 7; 13 - Peristaltic pump KORNET 7 bin (0,5 m³); 14 - Control chamber of peristaltic pump KORNET 7.

In order to satisfy the constantly increased demand for foam concrete products the special attention is paid to problems of development of modern mini-plants to produce such construction material. The industrial equipment is always improved, the automatics degree of all production processes increases constantly. Al these actions are made for only one purpose to get qualitative products met fully the modern demands.

The engineering enterprise "Stroymechanika" going with the times, designs and supplies the reliable and highly profitable equipment to produce foam concrete. The equipment produced by our enterprise is a turnkey production line allowing to make foam concrete mortars and mould high qualitative geometrically exact foam blocks.

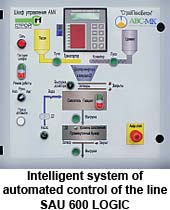

The automation of engineering processes of foam concrete articles production allows not only to reduce the prime price of final products, but increase considerably the stable character of its main features minimizing the influence of human factor especially at components batching. The automated system SAU 600 LOGIC is included in the AMK to solve the task of process automation.

The system SAU 600 LOGIC adjust the operation of:

The system SAU 600 LOGIC adjust the operation of:

- Silo with screw conveyor of "VK" series (cement conveyance);

- Belt conveyor LK 500 (inert aggregate conveyance);

- Weighting bin of inert and binding materials (weigh batching of inert and binding materials entering the mixing plant);

- Slide gate "Butterfly" with air-operated drive (loading of mix basic components into mixing plant);

- Liquid components preparation and batching plant SJK 4000 (batching supply of water and liquid components to the mix);

- Mixing plant "HYACINTH" (foam concrete mix making);

- Sphincter valve of ready mix unloading from mixing plant (unloading of ready mix).

The approximate layout of the line AMK "StroyFoamBeton 80 SK" on the production site:

1. Raw material storage.

The special bins (silos) are used to receive and store cement. The volume of the cement silo is determined not only by required capacity of the AMK line, but the schedule of cement supply. The cement is loaded into vertical silo by help of air-oeprated system of eth cement truck. The standard cement silo is equipped with bag filter SFCA, load cells of upper and lower cement level of SH series, aeration system. These components are of  production (MIX S.r.l., Italy). Sand is supplied on eth building site in dump trucks. The sand is loaded into feed bin for inert materials that is installed above belt conveyor of LK series and its analogue.

production (MIX S.r.l., Italy). Sand is supplied on eth building site in dump trucks. The sand is loaded into feed bin for inert materials that is installed above belt conveyor of LK series and its analogue.

2. Liquid components preparation area.

Water is poured into plastic tanks of the preparation and batching plant SJK through pipelines in given order. The concentrate and all required water are poured into the foaming agent tank, the required water and additives are poured into chemical agents tank. The liquid components (foaming agents and chemical additives solutions) are mixed by recycling pumps built in sidewall of the tank, are heated by heating elements.

3. Mixing area.

The mixing section includes: metering bin of inert and binding materials on the frame, mixing plant with embedded foam generator TRITON 5M, compressor K2. The water and liquid components are pumped in given order in concrete mixer. The cement enters the metering bin through screw conveyor of "VK" series, then, enters the mixing plant in accordance with rate of application for correspondent concrete density. The sand enters the metering bin and then mixing plant from feed hopper of inert materials with help of belt conveyor. After that all components has been loaded, the mortar is mixed to homogeneous mass, then the technical foam of given ratio multiplicity factor enters the mixing plant RBS HYACINTH by help of foam generator where the mix is mixed for ready mass.

4. Moulding area.

The ready foam concrete mix is evenly pumped into moulds FORM MASSIVE through drain valve of the mixer RBS 1000 HYACINTH by excessive pressure. A mould consists of two parts - a technological pallet and removable interchangeable borders. The technological pallet is four-wheel trolley with metal foundation. Before to pour the foam concrete mix the removable borders are greased and installed on the pallet.

5. Foam concrete sawing area.

As the foam concrete is hardened, the locks of borders of the FORMBLOCK MASSIVE are opened, the massive is removed from foundation and moulded foam concrete massive is entered the working area of the cutting plant URK MASTER PLUS LOGIC on the technological pallet. The massive is passed through screw knife of the cutting plant, then it is supplied under carriage of the cross cutting then under the carriage of length cutting. The carriages are lifted and with help of electric-powered drive, and string travel with help of gear motor. After the cutting cycle is made, the foam concrete articles are removed from the mould pallet and are transported to dry up.

6. Heat processing area.

Using the tracked locomotion techniques in the production shop the heat processing section is equipped with technological tunnels where the hot air is boosted by convector heaters or the "heat-insulated floor" are built in the foundation, as well as the installation of heating radiator is possible. The chamber use allows to accelerate the setting process as well as to get foam concrete with increased strength characteristics.

7. Foam concrete finished-products storage area.

After thermal processing the finished blocks are palletized, and wrapped with film. The pallets with foam concrete blocks are kept in finished-products storage area before 70% hardening. The temperature should be no less than +15°С. The pallets with blocks are stacked in three rows, the minimal area is estimated on the base of everyday capacity.

The competitive advantages of the AMK "StroyFoamBeton 80 SK":

- Operation in manual and automatic mode due to high automation level;

- Application of spare parts of well-known world manufacturers: components for air-operated system

(FESTO, Germany), gear motors of

(FESTO, Germany), gear motors of  (MOTOVARIO, Italy), control chamber components

(MOTOVARIO, Italy), control chamber components  (LG, South Korea),

(LG, South Korea),  (ABB, Germany), logical controllers of

(ABB, Germany), logical controllers of  (ABC-MK, Russia);

(ABC-MK, Russia); - High batching accuracy of used materials: 0,1%-0,2% allows to reduce the prime price;

- The geometrical accuracy and well-designed general view of ready products will satisfy the most exacting customer;

- High capacity ensures the productive efficiency.

Content of the line AMK "StroyFoamBeton 80 SK" capacity 80 m³/shift:

| № | Designation | Technical characteristics | Quantity, ps. |

|---|---|---|---|

| 1 | Cemnet silo of 50 m³ (full arrangement) with screw conveyor VK 219 (cement conveyance) | Tank diameter 2,4 m, tank height 11,4 m | 1 |

| 2 | Belt conveyor LK 500 with loading bin (7,4 meters) (sand conveyance) | Overall dimensions 8000×1020×595 mm Power consumption 5 kW Capacity 10 t/h |

1 |

| 3 | Metering bin of inert and binding materials with knife gate | Overall dimensions 2060×2060×3117 mm Air-operated drive of the knife gate of FESTO production |

1 |

| 4 | Mixing complex RBS 1000 HYACINTH with slide gate and pneumatic valve | Overall dimensions 1750×1200×1850 mm Power consumption 11 kW Capacity up to 10 m³/h |

1 |

| 5 | Automatic control system SAU 600 LOGIC | LG element base Overall dimensions 600×360×600 mm |

1 |

| 6 | Control box of system conctrrol of FESTO production | FESTO air-operated drive (Germany) Overall dimensions 600×500×200 mm |

1 |

| 7 | The liquid components preparation and batching plant SJK 4000 | Overall dimensions 2500×2100×1165 mm Power voltage 380 V |

1 |

| 8 | Universal cutting plant URK MASTER PLUS LOGIC | Overall dimensions 3600×2400×2700 mm | 1 |

| 9 | Metal mould FORMBLOCK-MASSIVE | Overall dimensions 1450×1450×750 mm | 1 |

| 10 | Air compressor К 2 | Overall dimensions 130×62×125 mm Power consumption 5,5 kW |

1 |

| 11 | Peristaltic (hose) pump KORNET 7 | Overall dimensions 1190×850×641 mm Weight 170 kg |

1 |

| 12 | Peristaltic pump KORNET 7 bin (0,5 m³) | Overall dimensions 1300×1100×1100 mm Weight 250 kg |

1 |

| 13 | Control box of peristaltic pump KORNET 7 | Overall dimensions 395×310×220 mm | 1 |

| 14 | Cables | 1 | |

| 15 | Air-operated system hose FESTO Ø8 mm | 1 |

|

|

|

| Cement silo of 50 m³ | Universal cutting plant URK MASTER PLUS LOGIC | Metering bin of inert and binding materials with knife gate |

|

|

|

| Mixing plant RBS HYACINTH | Peristaltic (hose) pump KORNET 7 | Liquid components preparation and batching plant SJK 4000 |

The line "StroyFoamBeton 80 SK" enters the customer run and tested.

The delivery set of the line includes::

- Operating manual;

- Service manual for SAU 600 LOGIC;

- Engineering schedule for production of articles on the line AMK "StroyFoamBeton".

| Optional equipment |

| About us | ||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

| Services | ||||||||||||||||||||||||

|

Consultations and services in the building materials production Development of technical specifications and technological schedules Contract supervision of the equipment |

||||||||||||||||||||||||

| Our dealers | ||||||||||||||||||||||||

|

||||||||||||||||||||||||

| © 2004-2009 "Stroymachanika" LTD | Catalogue Dealers About us News Contacts Site map |